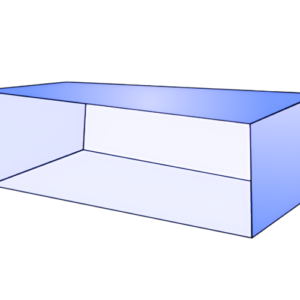

Double Glue Side Wall

Double Glue Side Wall is a construction technique used in the manufacturing of certain types of furniture, particularly in the case of wooden furniture. It involves the application of two layers of adhesive or glue on the side walls of furniture panels, resulting in increased strength and durability. The purpose of using double glue side walls is to enhance the overall structural integrity and longevity of the furniture. By applying two layers of glue, the bonding between the wooden components is significantly reinforced, making it less prone to splitting or coming apart under stress.

TELL US YOUR REQUIREMENTS

REQUEST A QUOTE

REVIEWS

Description

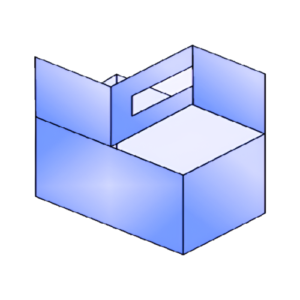

The Double Glue Side Wall is a construction technique used in various industries, particularly in the manufacturing of furniture, cabinets, and other wooden products. It refers to a method of joining two wooden panels together using a double layer of adhesive or glue.

In this technique, two panels of wood are placed parallel to each other, with their edges in close proximity. A layer of high-quality adhesive or glue is applied to both surfaces, ensuring a strong and secure bond. The panels are then pressed firmly together, allowing the glue to dry and form a solid connection.

The use of a double layer of glue provides several advantages. First, it enhances the overall strength and stability of the joint, making it more resistant to external forces and reducing the risk of separation. This is particularly important in applications where the joined panels will be subjected to heavy loads or stress.

Additionally, the double glue side wall technique helps to improve the aesthetics of the finished product. By creating a seamless and invisible bond between the panels, it eliminates the need for visible fasteners or unsightly gaps, resulting in a clean and professional appearance.

Furthermore, this construction method offers enhanced durability and longevity. The double layer of adhesive provides extra protection against moisture, humidity, and other environmental factors that can potentially weaken the joint over time. This makes the double glue side wall particularly suitable for applications in humid or moisture-prone environments.

Overall, the double glue side wall technique is a reliable and efficient method of joining wooden panels, ensuring both structural integrity and visual appeal. Its widespread use in various industries is a testament to its effectiveness in creating durable and aesthetically pleasing products.

SPECIFICATION

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up |

| Turn Around Time | 10-12 Business Days , Rush |