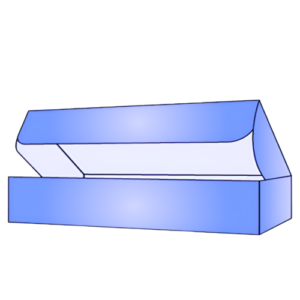

Full Overlap Seal End

A full overlap seal end is a type of packaging closure commonly used in various industries to secure and protect products. It is particularly prevalent in the food, beverage, pharmaceutical, and consumer goods sectors. The full overlap seal end is designed to provide a secure and tamper-evident seal, ensuring the integrity of the packaged contents. The construction of a full overlap seal end involves folding and overlapping the end flaps of the packaging material to create a sturdy and reliable closure. This type of seal provides excellent protection against moisture, dust, and other contaminants, helping to maintain the quality and freshness of the packaged items.

TELL US YOUR REQUIREMENTS

REQUEST A QUOTE

REVIEWS

Description

Full overlap seal end is a packaging design technique commonly used in the manufacturing of folding cartons and boxes. It is a specialized closure method that provides complete coverage and protection to the contents within the package. This type of seal end is known for its secure and sturdy construction, ensuring that the packaging remains intact during storage, transportation, and display.

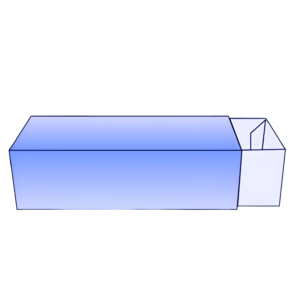

The full overlap seal end is achieved by precisely folding the carton’s flaps and tucking them inside each other, creating a seamless and continuous closure. Unlike other closure methods that leave a partial opening, the full overlap seal end completely covers the edges of the box, eliminating any gaps or exposed areas. This not only enhances the aesthetic appeal of the packaging but also enhances its functionality by preventing dust, moisture, and other external elements from entering the package.

The full overlap seal end provides excellent protection to a wide range of products, including fragile and perishable items. It offers increased structural integrity, making the package more resistant to crushing and impacts during handling and shipping. This feature is particularly advantageous when dealing with delicate or high-value goods that require extra care and protection.

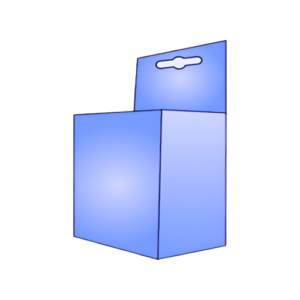

Furthermore, the full overlap seal end enables easy opening and access to the contents of the package. It typically incorporates user-friendly features such as tear strips, perforations, or tabs that facilitate the opening process without compromising the integrity of the packaging. This ensures a seamless and hassle-free experience for both consumers and retailers.

From a branding and marketing perspective, the full overlap seal end offers ample space for creative and informative graphics. Manufacturers can utilize the large surface area of the package to showcase branding elements, product information, promotional messages, and eye-catching designs. This helps in grabbing the attention of potential customers and communicating important details about the product.

Overall, the full overlap seal end is a reliable and versatile closure method that combines functionality, protection, and aesthetics. Its robust construction ensures the integrity of the packaging while providing an excellent user experience. Whether used for retail products, food items, or any other goods, the full overlap seal end offers an effective and attractive packaging solution.

SPECIFICATION

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up |

| Turn Around Time | 10-12 Business Days , Rush |