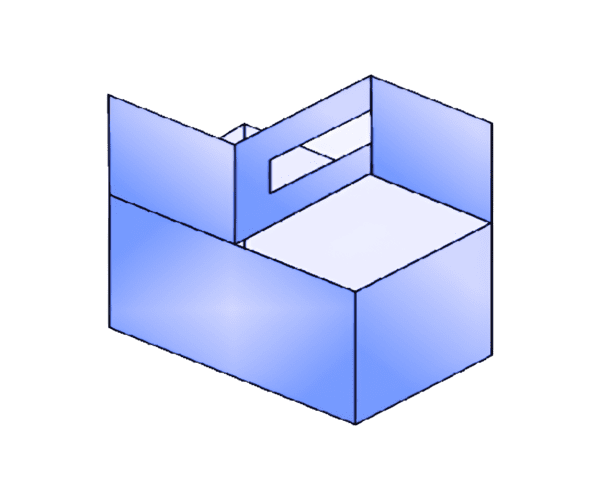

Glass Carrier

A glass carrier is a specialized device or tool designed to safely transport and handle glass products. Glass is a fragile material that can easily break or shatter, making it challenging to handle and transport without proper precautions. Glass carriers provide a secure and convenient solution for moving glass items, whether they are flat sheets, panels, or other glass-based products. The primary purpose of a glass carrier is to protect the glass from damage during handling and transportation.

TELL US YOUR REQUIREMENTS

REQUEST A QUOTE

REVIEWS

Description

Glass Carrier is a versatile and durable transportation system designed specifically for the safe and efficient handling of glass products. It is a specialized solution that ensures the protection of fragile glass materials during storage, transportation, and installation processes.

The carrier itself is typically made of sturdy materials such as steel or aluminum, incorporating features that securely hold the glass panels in place. These carriers come in various sizes and designs to accommodate different types and dimensions of glass, ranging from small sheets to large windows or glass panels.

One of the key features of a glass carrier is its protective padding or cushioning, which helps absorb shocks and vibrations to prevent breakage or damage to the glass. This padding is often made of materials like foam or rubber that offer excellent shock absorption properties while maintaining a secure grip on the glass.

Glass carriers may also include adjustable clamps or straps that can be customized to fit different glass sizes and shapes securely. These clamps or straps provide an additional layer of support and prevent any movement or shifting of the glass during transportation, further minimizing the risk of damage.

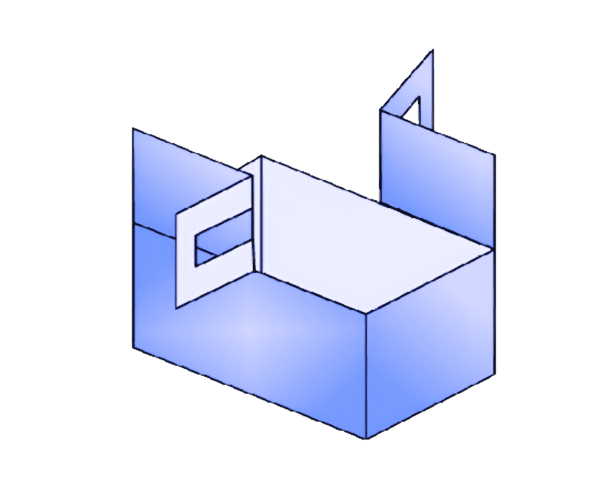

Additionally, glass carriers are designed with user-friendly features to facilitate ease of use and convenience. They often have handles or grips for ergonomic lifting and maneuvering, allowing workers to transport glass safely and efficiently. Some carriers may also include wheels or casters for easy mobility, especially when handling larger and heavier glass panels.

Glass carriers are commonly used in various industries such as construction, architecture, manufacturing, and automotive, where the transportation of glass products is a frequent requirement. They play a crucial role in ensuring the integrity and quality of the glass materials throughout the supply chain, from production facilities to installation sites.

Overall, glass carriers provide a reliable and secure solution for the transportation of delicate glass products. By offering enhanced protection, ease of use, and adaptability to different glass sizes, they contribute to reducing the risk of breakage and damage, ultimately saving time, costs, and resources for businesses involved in the glass industry.

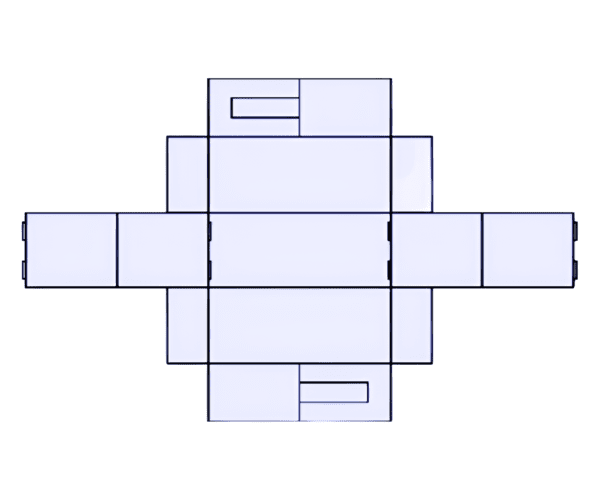

SPECIFICATION

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up |

| Turn Around Time | 10-12 Business Days , Rush |