Reverse Tuck End

The reverse tuck end is a packaging design feature commonly used in the creation of folding cartons. It is a specific type of tuck end closure that provides secure sealing and easy access to the contents of the package. The reverse tuck end is often favored for its simplicity, functionality, and aesthetic appeal. In a reverse tuck end design, the ends of the carton fold inward in opposite directions. The top closure tucks into the back panel, while the bottom closure tucks into the front panel. This arrangement ensures a snug fit and offers additional protection to the contents of the package.

TELL US YOUR REQUIREMENTS

REQUEST A QUOTE

REVIEWS

Description

The Reverse Tuck End (RTE) is a popular packaging design used in various industries, especially in the field of consumer goods and retail. It is a type of carton structure commonly employed for small to medium-sized products such as cosmetics, electronics, food items, pharmaceuticals, and more.

The Reverse Tuck End is characterized by its unique opening and closing mechanism. The box features two main panels that meet at the center, where the top panel tucks into the bottom panel. Unlike the conventional tuck end style where the top panel tucks in the rear, the reverse tuck end design has the top panel folding inward to the front of the box, creating a neat and secure closure.

This packaging style offers several advantages. Firstly, it provides easy access to the product inside. With a simple pull on the top panel, the box opens smoothly, allowing for convenient retrieval of the item. Additionally, the reverse tuck end design ensures a snug fit, preventing the product from slipping out or becoming loose during transportation or display.

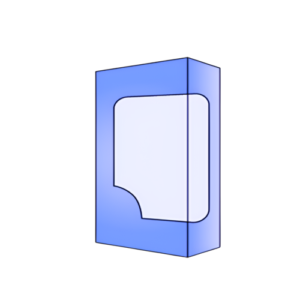

The Reverse Tuck End is known for its versatility. It can be customized in various sizes, shapes, and materials to suit specific product requirements. Whether it’s a small box for individual items or a larger container for multiple products, the RTE can be tailored to accommodate diverse packaging needs.

Another notable feature of the Reverse Tuck End is its printable surface area. The exterior of the box provides ample space for branding, product information, graphics, and promotional messages. This allows companies to effectively communicate their brand identity and engage customers through visually appealing designs.

In terms of assembly, the Reverse Tuck End is relatively easy to set up. The box can be manually folded and locked into place without the need for additional adhesives or tools. This simplicity makes it a cost-effective packaging solution, both in terms of production and assembly.

Overall, the Reverse Tuck End is a practical and visually appealing packaging style that combines functionality, convenience, and aesthetics. Its secure closure, easy access, and customizable features make it a popular choice for companies seeking a reliable and attractive packaging solution for their products.

SPECIFICATION

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up |

| Turn Around Time | 10-12 Business Days , Rush |