Description

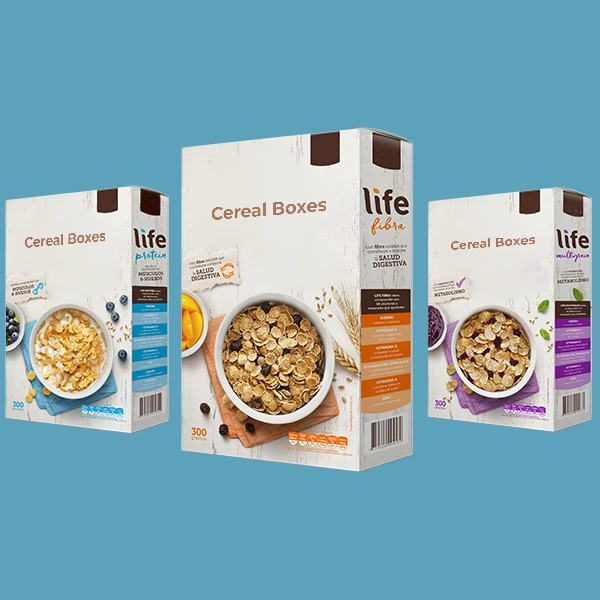

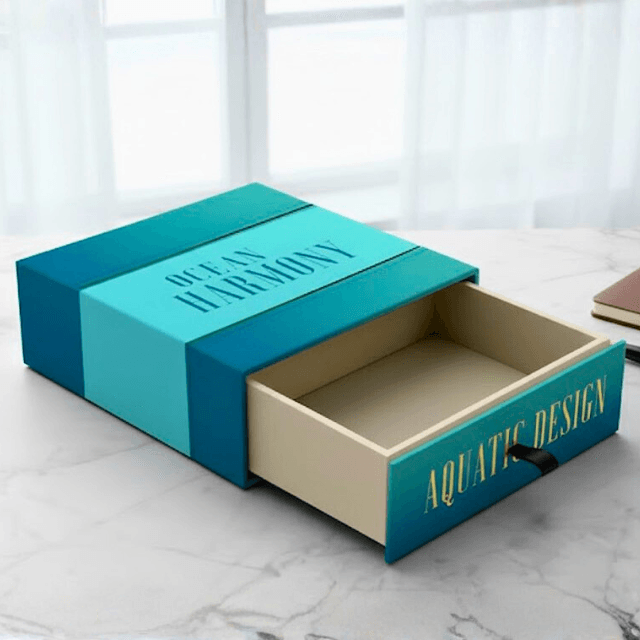

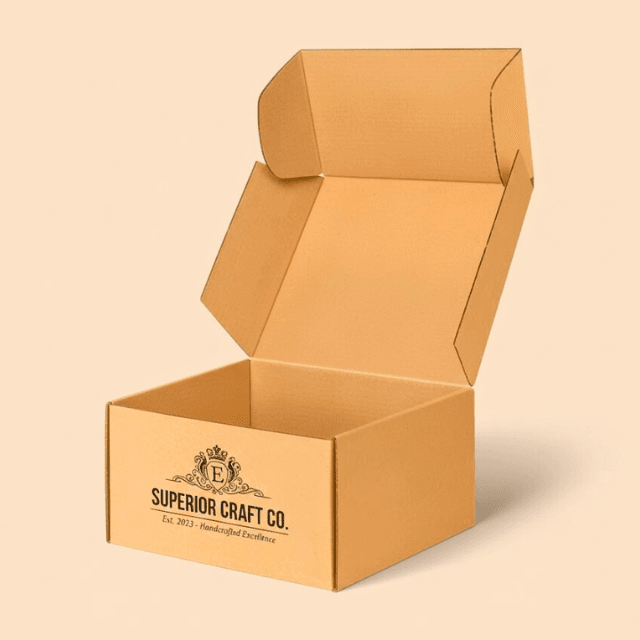

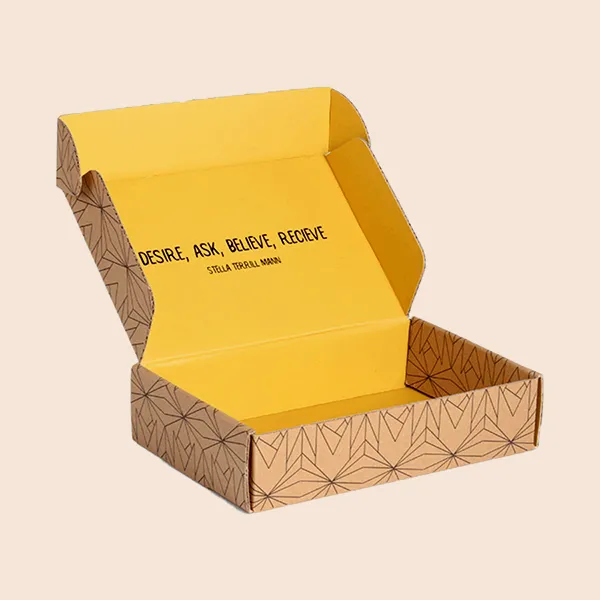

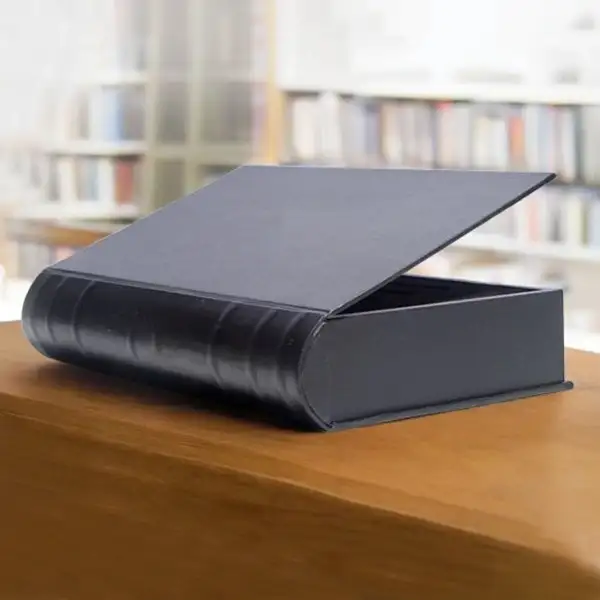

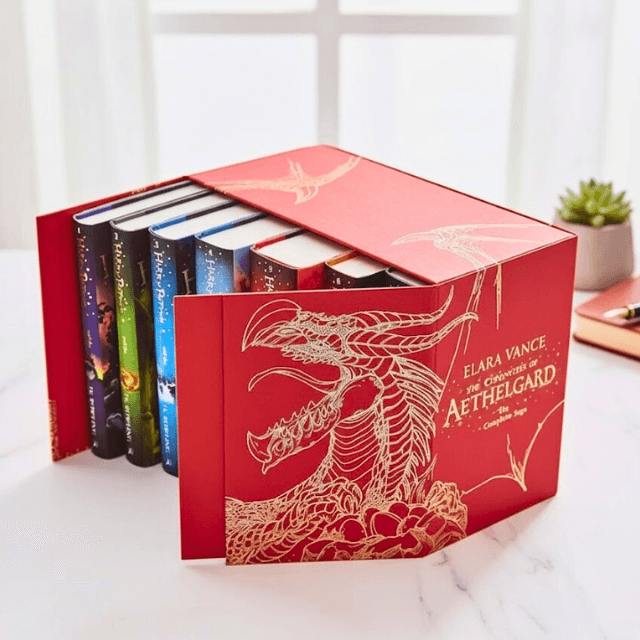

Custom Roll End Tuck Top Boxes with Quality Printing and Designing

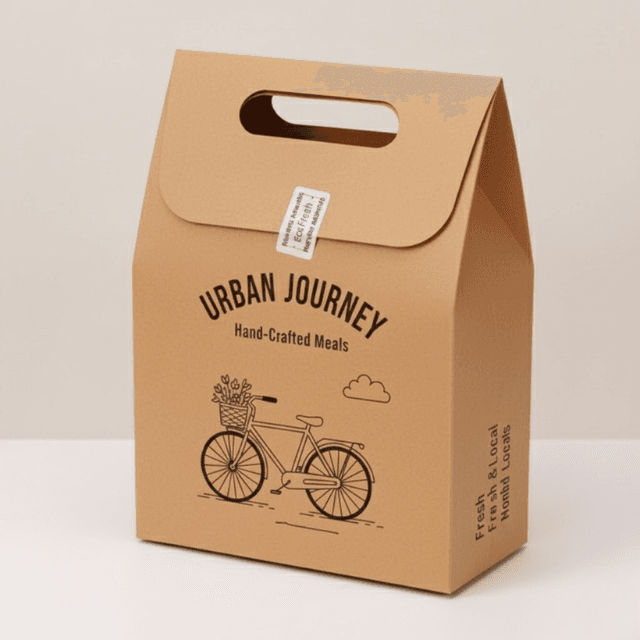

Many problems and obstacles arise in the assembling, packaging, inserting, and shipping of a product. Roll end tuck top boxes are the most effective method for this task. These boxes include pre-creased folds that make assembling a simple three-step operation. In addition, roll end tuck boxes provide a broad and deep space for storing goods. These Custom tuck boxes may be quickly and easily prepared for shipment because of the top lid’s ability to tuck automatically into the bottom foundation. After being built and sealed, roll end boxes lie flat from the bottom up, making them easy to handle and move in stacked delivery trucks or warehouses. Faster product packaging and shipping are made possible with us.

Deliver Safely with Custom Roll End Tuck Top Boxes

Breakage of products during transit or delivery of semi-damaged things to clients is a significant worry for firms sending products to customers and transferring goods. The easiest way to get the necessary strength, ship items with enhanced protection, and guarantee their safe arrival is to use a bespoke roll end tuck front box, whether you’re sending them across town or the globe. Roll end tuck top boxes feature a double wall structure that offers increased strength to prevent damage from bending and structural collapse. In addition, the construction of roll end custom boxes is reinforced when the lid is tucked into the base.

Materials We Use to Make Roll End Tuck Boxes?

Custom Roll end tuck top boxes are the best option if you need more protection, want to avoid collapse, or want to keep safely putting delicate items away from any harm. But, creating such very stiff and extra secure roll end tuck boxes is no fun and demands tremendous experience and understanding about materials, protective designs, and inserts. In such circumstances, OXO Packaging is the perfect packaging solutions supplier and bespoke roll end tuck top box mass production services business.

Selection of Material

Material is essential in offering protective features to bespoke tuck top boxes. In this regard, our seasoned material experts are well-versed. First, they question your chosen material option. Then, if you need help deciding on the best shipping method, they’ll do it for you based on the dimensions and weight of your order. Then they assist you in picking the appropriate material for desired degree, robustness & quality function deployment of bespoke Tuck End Boxes.

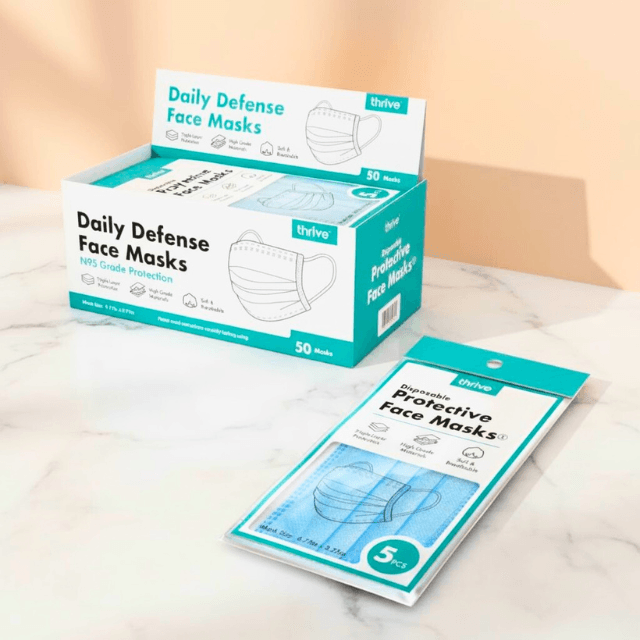

Cardboard Material

Obtaining protective but aesthetically pleasing cardboard boxes is ideal for packing and shipping lightweight, high-end items. Choose a cardboard stock of 14 pt for sufficient durability for mailing light items and a supply of 24 pt for added sturdiness when mailing hefty, high-end products across long distances.

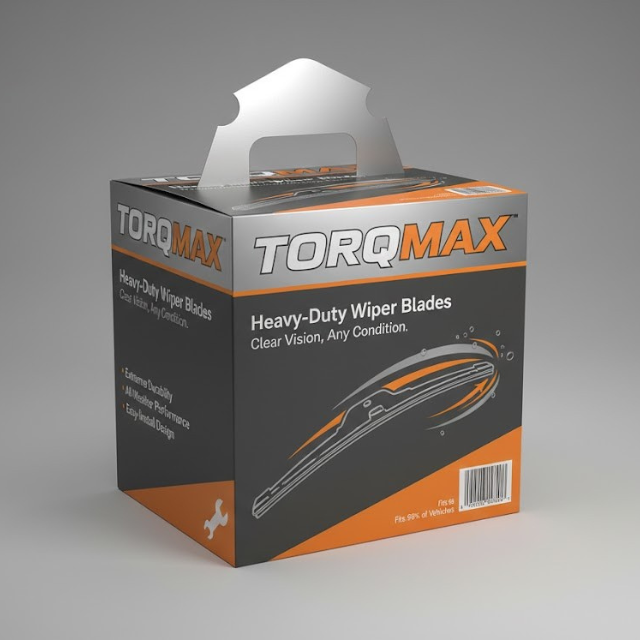

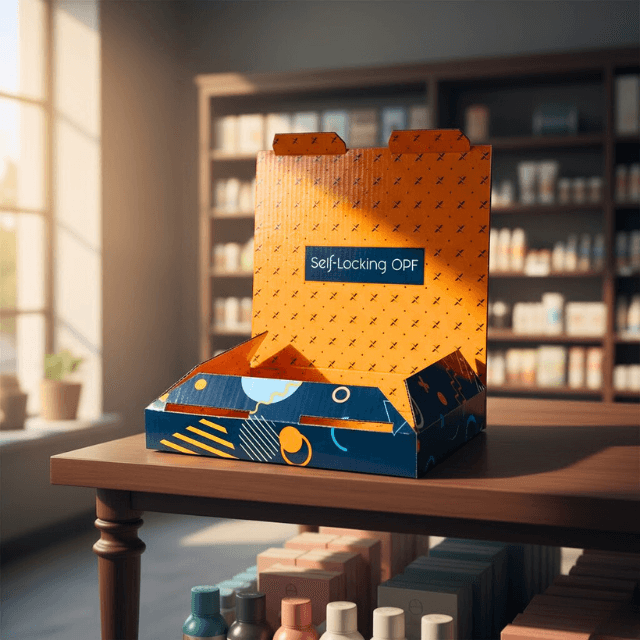

Corrugated Material

For sending oversized, delicate items that must be shielded from crushing and damage, corrugated cardboard is an excellent product for your bespoke roll end tuck top boxes. Choose between G-flutes, which are thin but still have suppressive capabilities, and C-flutes, which are substantial but give ultimate minimization of stresses and smash serious harm to boxes and inside contents, according to the size, weight, and distance of the goods being sent.

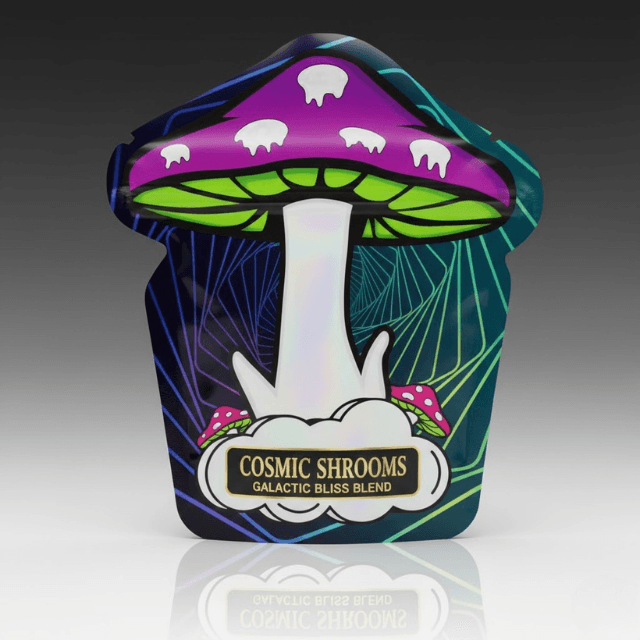

Kraft Material

Nothing beats the recyclable and tear-resistant properties for keeping boxes utterly biodegradable without sacrificing durability. Likewise, herbal and organic items should be packaged eco-friendly without regard to their potential harm from the elements.

Read More: How Customized Tuck Boxes Can Enhance Your Product Sales

What Makes OXO Packaging Different from the Rest?

OXO Packaging’s guiding principle is to make the customer’s experience as easy as possible. To deliver on this promise, our teams have collaborated, listened to client concerns, and developed guidelines that make it easier for them to order roll end tuck top boxes in the exact dimensions they need. Use the following guidelines and standards to make ordering roll end tuck front box easy, quick, and satisfying.

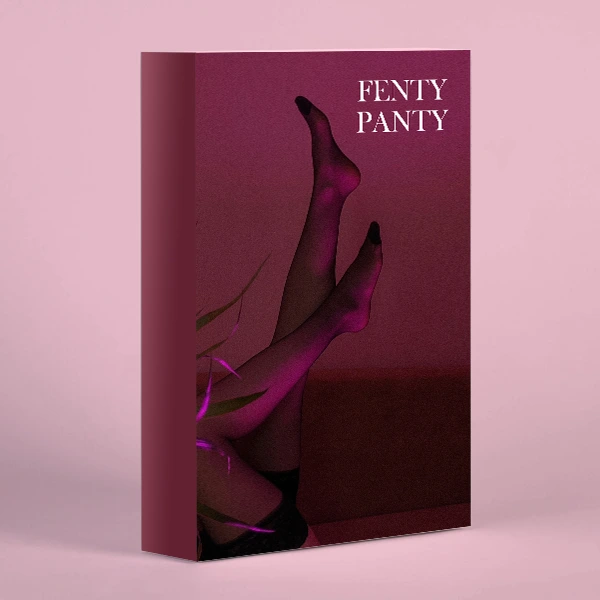

Reusable Roll End Tuck Top Boxes

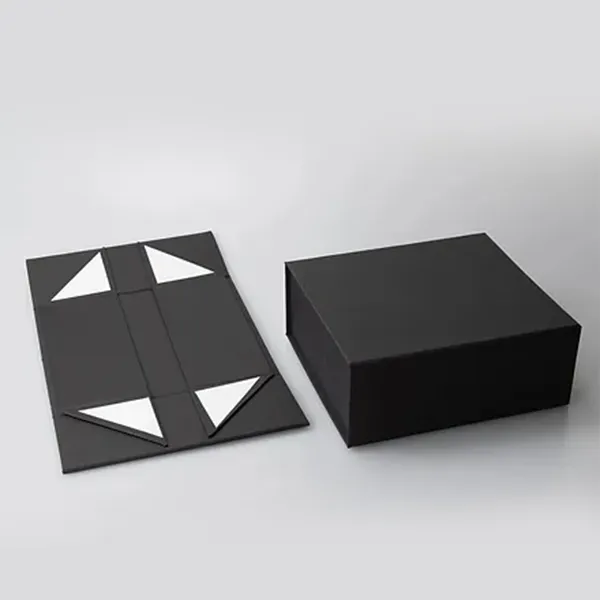

The custom printed roll end tuck top boxes are manufactured using innovative but environmentally friendly, printing processes and cutting-edge machinery at a printing facility that complies with worldwide environment conservation standards.

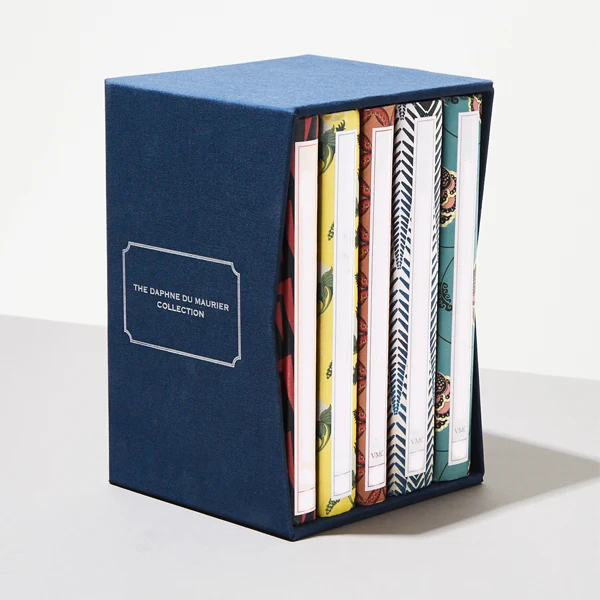

All Sizes Available

It is no longer easier to get the Reverse Tuck Boxes you want in the dimensions you specify. Our packaging experts will offer you a 3D mockup and die line for your roll end boxes, complete with measurements for the box’s interior and exterior creases and depths, so you can be sure the final product will be the right size for your goods. Our skilled die-cutting engineers take the time during production to precisely configure the computer-controlled die-cutting equipment with the needed dimensions and execute test cycles to guarantee that the desired box size will be achieved. Then, when everything checks out, the bulk die-cutting procedure may begin.

Free Design Consultation

You’ve got a digital mockup of your bespoke roll end tuck top boxes design, but you still need to be happier with it and are anxious about how it will turn out in final production. Do not worry! Having something physically in one’s hands facilitates a more thorough examination than just reading about it online. We may make a one-off sample of any box design and ship it to the buyer, so they can scrutinize it and get feedback from loved ones.

How to Reach us?

Custom box production and printing services are just two of the many packaging options offered by OXO Packaging, a United States-based industry leader. As a result of an astounding 99% approval rate from satisfied customers. Anytime, everywhere, we’re here to help with all your needs for bespoke roll end boxes. Get in contact with our specialists by calling or sending an email with any questions you may have, and we’ll get started on your order of bespoke roll end tuck top boxes right away.

How Long Will it Take for My Order to Be Processed?

Get your customized roll end tuck top boxes in less than 14 working days from the moment of design approval and permission from the client to dispatch the cargo. To ensure that the designing, printing, die-cutting, and manufacturing teams are all on the same page regarding communicating and managing die lines and boxes, we have implemented stringent working procedures and written communication channels. OXO Packaging is a trusted packaging supplier that can handle any size request. Our processes are fully automated.

Why Should I Choose You?

Obtain custom roll end tuck top boxes of the highest quality here with us. We create the finest custom roll end tuck front box. Because of this, we have a unique quality control division to monitor each shipment of boxes. Each set of roll end tuck top boxes is checked for quality according to a group of criteria and processes developed by highly skilled and experienced quality management examiners.