Seal End With Perforated Top

A SEAL END WITH PERFORATED TOP is a packaging solution commonly used in the food and beverage industry. It offers convenience, tamper-evidence, and easy access to the product. The sealed end refers to the closure mechanism at one end of the packaging, while the perforated top allows for easy opening by tearing along the perforation. This type of packaging is typically made from sturdy materials like paperboard or corrugated cardboard, which provide strength and durability. The sealed end is formed by folding and sealing one end of the packaging, creating a secure enclosure for the product inside. This ensures that the contents remain protected during transportation and storage.

TELL US YOUR REQUIREMENTS

REQUEST A QUOTE

REVIEWS

Description

A SEAL END WITH PERFORATED TOP is a type of packaging design commonly used in various industries, especially in the food and beverage sector. It is a specialized closure system that offers convenience, freshness, and tamper-evident features for products.

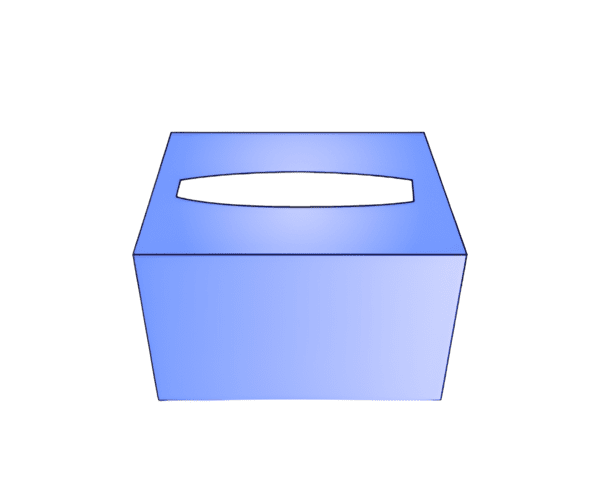

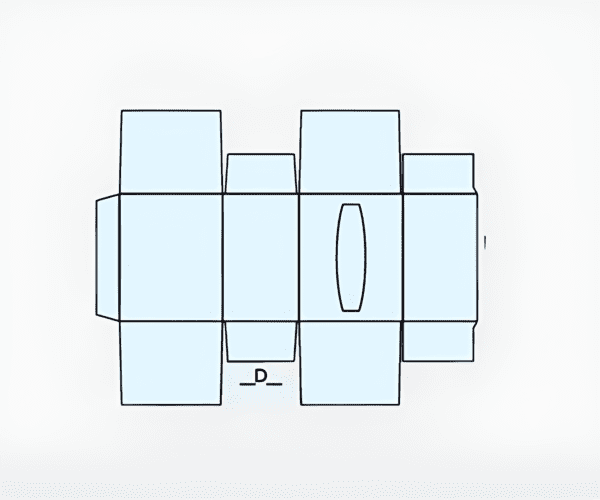

The sealed end refers to the structure of the packaging, which typically consists of a carton or paperboard material that is folded and sealed to create a sturdy and secure container. This design ensures that the contents of the package remain protected during handling, transportation, and storage.

What sets the seal end with the perforated top apart is the presence of a perforated section at the upper part of the packaging. This perforation allows for easy opening and access to the product inside. It provides a convenient tear line for consumers, eliminating the need for scissors or other tools to open the package.

The perforated top serves multiple purposes. Firstly, it enhances the user experience by enabling effortless and quick opening of the packaging, enhancing convenience and ease of use. Secondly, it ensures the integrity of the product by acting as a tamper-evident feature. Any attempt to open the package will result in visible damage to the perforated section, indicating potential tampering and alerting consumers to possible issues with the product’s safety or quality.

Additionally, the seal end with a perforated top offers advantages in terms of product freshness. The secure seal created by the packaging design helps to preserve the contents by preventing air and moisture from entering the package. This feature is particularly crucial for perishable items, such as food and beverages, as it helps to maintain their taste, aroma, and overall quality.

Overall, the seal end with a perforated top is a practical and user-friendly packaging solution that combines security, convenience, and freshness. It provides an easy-to-open feature while ensuring the safety and integrity of the product, making it a popular choice for a wide range of consumer goods.

SPECIFICATION

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up |

| Turn Around Time | 10-12 Business Days , Rush |