Tuck End Auto Bottom

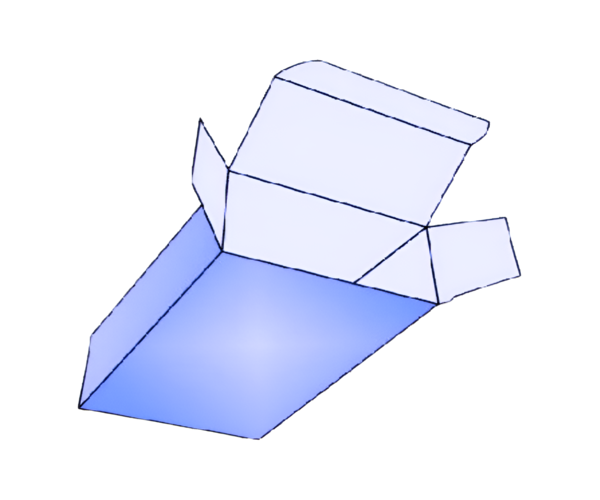

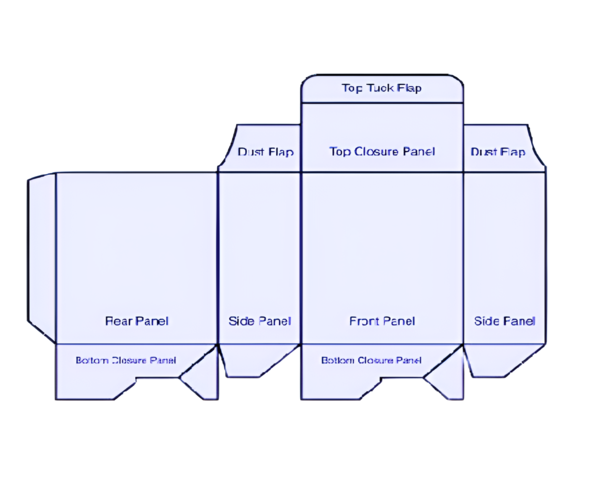

Tuck End Auto Bottom is a popular packaging design used in various industries, particularly in the realm of retail and consumer products. It is a type of folding carton packaging that offers convenience, functionality, and visual appeal. The name “Tuck End Auto Bottom” describes the specific construction and closure mechanisms of this packaging style. The term “Tuck End” refers to the closure method on both ends of the carton. The flaps on the top and bottom of the packaging are designed to be tucked inside the box, creating a secure seal. This tuck end closure provides protection to the contents of the package and ensures that it remains intact during handling and transportation.

TELL US YOUR REQUIREMENTS

REQUEST A QUOTE

REVIEWS

Description

Tuck End Auto Bottom is a popular packaging style used in the production of various consumer goods and retail products. It refers to a specific design and construction technique for folding cartons or boxes, providing convenience, security, and attractive presentation.

The term “Tuck End” refers to the flaps on the top and bottom of the box that fold inward to create a closure. These flaps are typically tucked into slots or slits on the opposing side panels, securely sealing the box. The “Auto Bottom” feature denotes an automatic locking mechanism at the bottom of the box, allowing for quick and easy assembly without the need for additional adhesives or tape.

One of the key advantages of Tuck End Auto Bottom packaging is its structural stability and strength. The auto bottom feature ensures that the box remains securely closed, even when subjected to handling, transportation, or stacking. This design eliminates the risk of accidental opening, providing reliable protection for the enclosed product.

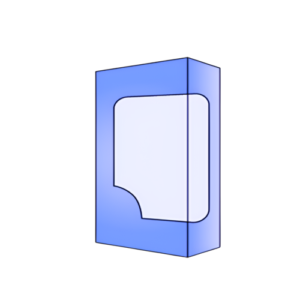

Tuck End Auto Bottom boxes are highly customizable, allowing for various shapes, sizes, and printing options to meet specific branding and marketing requirements. The smooth exterior surfaces provide ample space for product information, logos, promotional messages, or eye-catching designs, enhancing the overall aesthetic appeal and shelf presence.

This packaging style is widely used across industries, including food and beverages, cosmetics, electronics, pharmaceuticals, and more. It is particularly suitable for products that require a professional and visually appealing presentation while ensuring product integrity and security. The ease of assembly and reusability of Tuck End Auto Bottom boxes also contribute to their popularity among both manufacturers and consumers.

In summary, Tuck End Auto Bottom packaging offers a combination of functionality, durability, and visual appeal. It provides a reliable solution for product packaging, ensuring easy assembly, secure closure, and an attractive presentation for various retail items.

SPECIFICATION

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up |

| Turn Around Time | 10-12 Business Days , Rush |